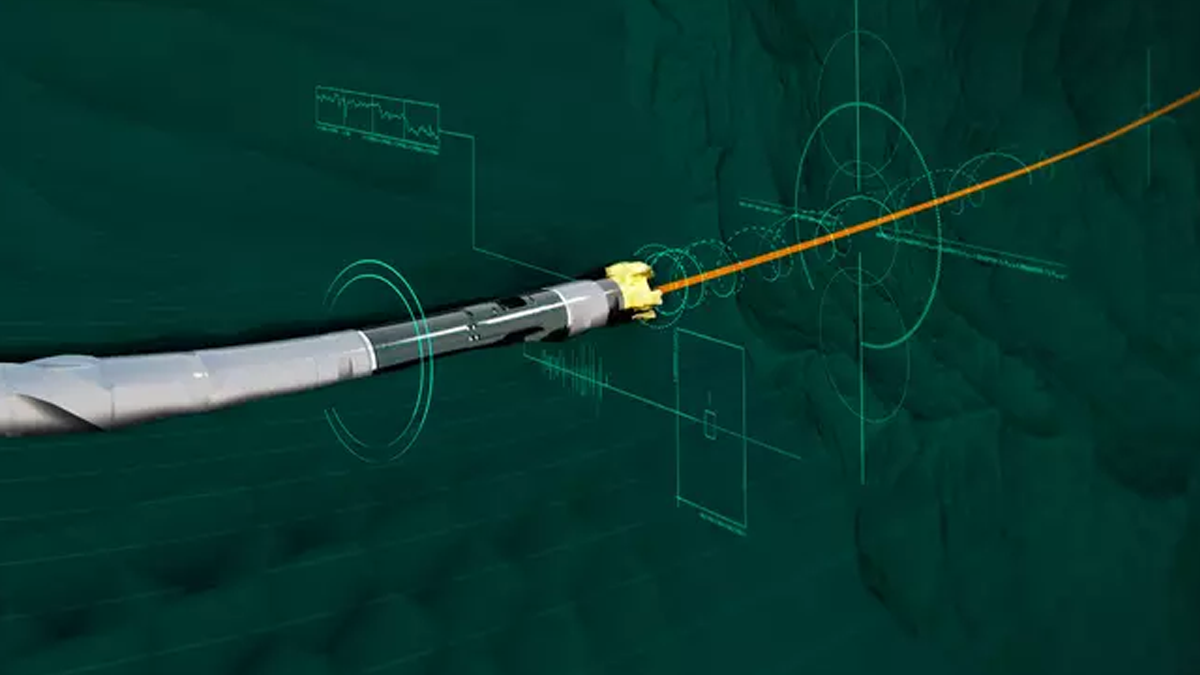

i-Trak Drilling Automation Service -Automated trajectory drilling

The i-Trak™ Automated Trajectory Drilling service is a software application running on a dedicated server on the rigsite. This software solution generates steering parameters based on the comparison of the planned well trajectory with actual survey measurements. Using hole quality KPI’s such as minimum added dog-leg severity and optimized number of downlinks it enables to maintain the well close to the planned trajectory and to drill a high quality well within a pre-planned drilling corridor.

Improve your drilling performance, wellbore quality, and trajectory with i-Trak™ drilling automation services from Baker Hughes. By integrating and automating your drilling systems, the i-Trak services improve the safety, speed, and economics of your drilling operations by moving your personnel from the wellsite to remote operating centers. You get improved drilling performance, wellbore quality, and trajectory with services that aggregate real-time surface and downhole data. Further risk reductions and time savings are achieved by implementing hybrid physics-based and data-driven models with automated, standardized operating procedures and checklists.

i-Trak drilling automation services deliver in three critical areas: • Providing fully closed-loop, automated trajectory drilling from Baker Hughes rotary steerable tools • Delivering automated reservoir navigation services for increased recovery • Analyzing wellbore hydraulics and static loads • Tracking drilling dynamics in real time Our services offer you two types of automated control. An “advisory mode” recommends actions or parameters that must be approved by the driller. A “closed-loop mode” automatically downlinks parameter changes and instructions to the downhole tools. While these systems are automated, the driller stays in the loop and can start or stop the system at any time. Automation of your drilling systems is critical in today’s competitive and complex drilling environment. i-Trak drilling automation services help you achieve safe, efficient, and predictable drilling performance every time, while reducing your operational risks and well delivery costs.

Features and Benefits • Software application capable of predicting the wellbore trajectory, deriving steering proposals to follow the planned trajectory closely or steer back to plan, and submitting those steering parameters automatically per downlink • Automate survey transfer to wellplanning system and trigger automated clearance scanning • Real-time calculation of distance from plan at survey position, bit and every meter down to 30m ahead of the bit • Automated alarms • Unburdens the directional driller by automatically generating steering parameters as advice or automated downlink • Facilitates remote operations • Enables Directional Driller to focus on exception handling, not routine events • Automated downlink

Applications • Onshore, offshore, and deepwater • Directional Drilling with AutoTrak G3 • Conventional and unconventional |