i-Trak Automation Service - Dynamics Management

The i-Trak™ Dynamics application is using CoPilot data to detect hard stringers in the drilled formation and provides computer assisted guidance how to drill such stringers minimizing the wellpath deviation or equipment damage caused by these stringers.

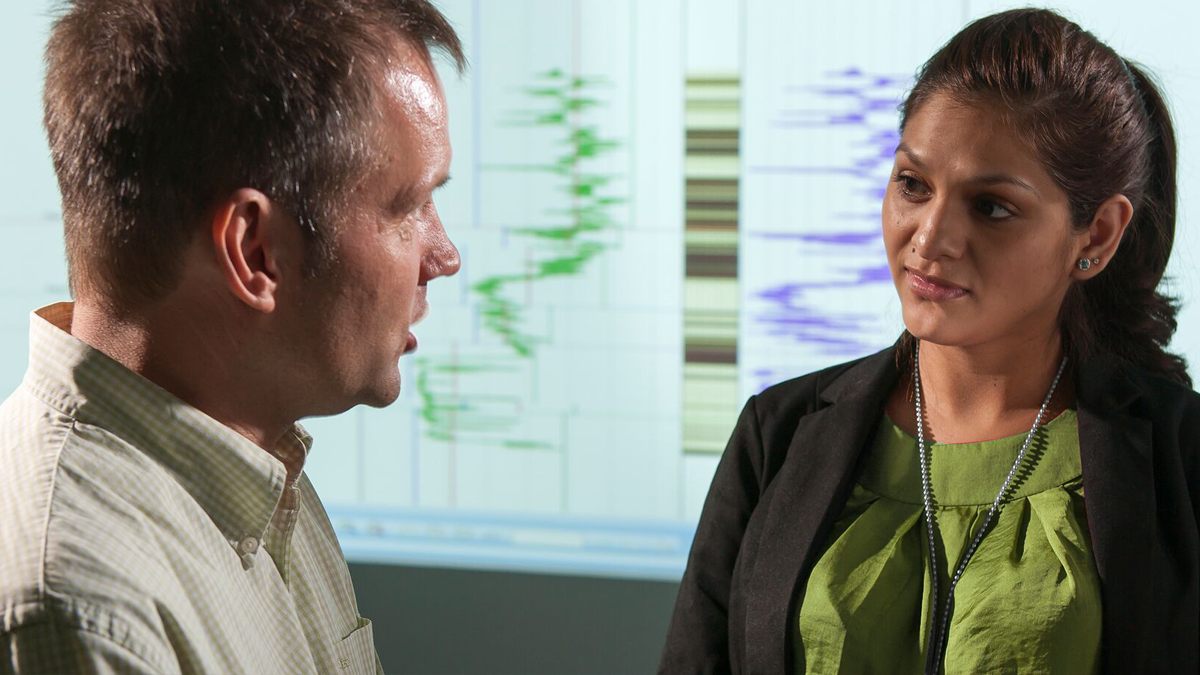

Improve your drilling performance, wellbore quality, and trajectory with i-Trak™ drilling automation services from Baker Hughes. By integrating and automating your drilling systems, the i-Trak services improve the safety, speed, and economics of your drilling operations by moving your personnel from the wellsite to remote operating centers. You get improved drilling performance, wellbore quality, and trajectory with services that aggregate real-time surface and downhole data. Further risk reductions and time savings are achieved by implementing hybrid physics-based and data-driven models with automated, standardized operating procedures and checklists.

i-Trak drilling automation services deliver in three critical areas: • Providing fully closed-loop, automated trajectory drilling from Baker Hughes rotary steerable tools • Delivering automated reservoir navigation services for increased recovery • Analyzing wellbore hydraulics and static loads • Tracking drilling dynamics in real time Our services offer you two types of automated control. An “advisory mode” recommends actions or parameters that must be approved by the driller. A “closed-loop mode” automatically downlinks parameter changes and instructions to the downhole tools. While these systems are automated, the driller stays in the loop and can start or stop the system at any time. Automation of your drilling systems is critical in today’s competitive and complex drilling environment. i-Trak drilling automation services help you achieve safe, efficient, and predictable drilling performance every time, while reducing your operational risks and well delivery costs.

Features and Benefits • Constant monitoring of drilling dynamics measurements from CoPilot and rig surface sensors to detect and mitigate NPT impact of hitting hard stringers in the formation. These interbedded hard formations typically lead to problems maintaining the planned trajectory, introduce local doglegs damaging the BHA or directly damage the bit. • Earliest detection of a stringer allows to react according to established procedures and to mitigate potential NPT from such event. • i-Trak Drilling Advisor provides the required workflow and operational procedures in real-time to the user. It is automatically triggered as soon as a stringer is detected.

Applications • All Drilling Environments • Drilling Formations with interbedded Hard Stringers |